Products that solve your problems

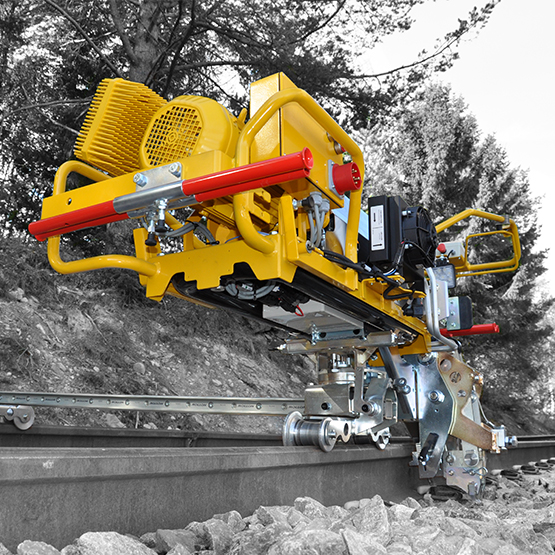

Rosenqvist CD200 Clipping Machine

A high performance, robust, walk-behind clipping machine, designed for use by a single operator and capable of achieving speeds of up to 30 sleepers per minute. Supplied with an electric starter and excellent lighting to improve visibility when working at night. Switching sides or working direction is simple and the machine is easy to carry on and off the track.

Pandrol QTrack® Embedded system for LRT

The Pandrol QTrack® is a continuously supported and fastened embedded ballastless track system, where the rail is completely encapsulated by elastic prefabricated resin bonded rubber profiles with a unique shape and adapted stiffness characteristics. The system, when installed in concrete, provides support to all sides of the rail and allows stringent vertical and lateral support criteria to be met, and at the same time offers vibratory and electrical decoupling from its surroundings. An installation rate of up to 144 lmst/day/work-group is feasible, making Pandrol QTrack® the quickest, easiest and most cost effective system available on the market.

Vanguard Fastening System

A unique rail fastening system with very low vertical dynamic stiffness that leads to high levels of vibration isolation. The significant reduction of vibration and secondary noise makes it ideal for applications in the most sensitive areas to these environmental concerns. Pandrol Vanguard assemblies are suitable for application on concrete and timber sleepers, slab track on bridges, tunnels and viaducts.

Rigid Catenary

Our rigid catenary system is an alternative rail transport power supply system to conventional catenary. Its characteristics make it the most widely used system in tunnels, although its lower maintenance costs justify its installation in a range of environments. Maintenance costs can be greatly reduced, as well as delivering increased current carrying capability and increased security. Our rigid catenary system can also reduce tunnel clearance against standard catenary system, so the construction cost is greatly reduced.

A world of knowledge

Golden Horn Bridge, Istanbul, Turkey

Connecting the two sides of Golden Horn as part of the M2 Istanbul Subway line, the Golden Horn Metro bridge is a swing bridge that can rotate horizontally to allow ships through. The curve on the surface of the steel bridge, which is necessary for drainage purposes and the gaps between the fastenings and the steel surface, posed a significant challenge. This was eventually solved through the use of steel platforms of adjustable height, which were specifically designed for this project.

The Pandrol VANGUARD rail fastening system was specified for the critical areas, around the historic structures and the Genoese Walls due to its sound and vibration suppression characteristics. The rubber wedges integrated in the VANGUARD system, which keep the rail suspended above the bridge surface, provide great flexibility, adding to the electrical isolation and help to provide vibration and sound suppression. The project was extremely successful and noise and vibration from the bridge have been kept to acceptable levels.

CBD and South East Light Rail, Sydney Australia

The CBD and South East Light Rail is a new light rail network for Sydney, with a 12 km route and 19 stops. Sydney Light Rail also incorporates the Inner West Light Rail which is now operating as the L1 Dulwich Hill Line, the 12.7km route connects Central Station and is used by 9.8 million customers ever year. This line serves one of the busiest intersections in downtown Sydney Central Business District from George Street to Market Street.

Pandrol QTrack® system was specified for the Sydney Tramway, which is a continuously supported and fastened embedded ballastless track system. A cost effective and long-lasting performance solution with an easy and straightforward installation process, QTrack® is easy to install and the Pandrol team provided technical support throughout the process, from specification right through to installation.

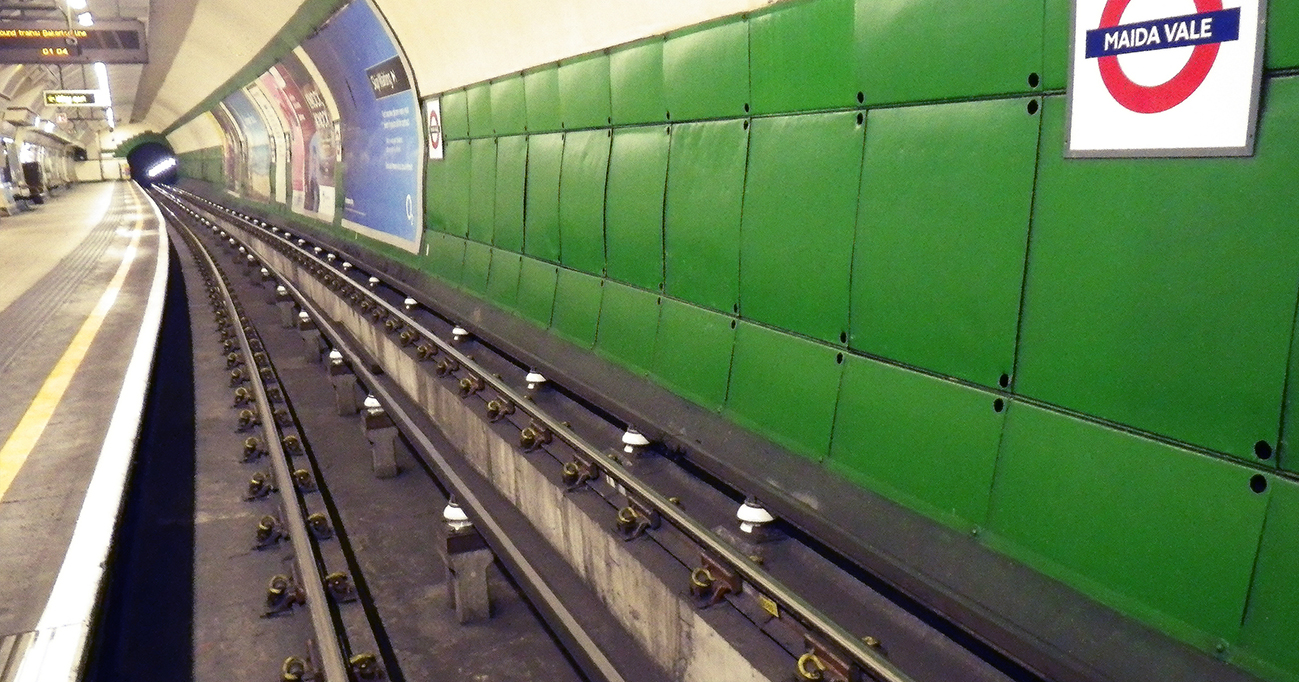

London Underground retrofit

The deep tubes on the London Underground have been gradually renewed over the last 30 years to replace the original bull head rail on timber sleepers with a modern concrete sleeper capable of supporting standard flat bottom rail. The original ‘e’clip assembly was relatively stiff and was designed at a time when vibration attenuation was not a major requirement and London Underground faced the challenge of complaints from neighbours and the general public about noise and vibration levels from its railway. The challenge was to attenuate vibration without changing the whole track, which meant it was necessary to substantially soften the rail fastening assembly to effectively cushion the structure of the tunnels from the track. Ground-borne vibration was then diminished into adjacent structures and adjoining properties.

The first noise and vibration remedial work was carried out on the Victoria Line in 1999 using Pandrol VANGUARD. Through laboratory testing work and producing a prototype system, the noise and vibration attenuation was measured, before and after installation. The VANGUARD assembly was found to reduce the amount of vibration in the neighboring building to below the level of background noise, making it impossible to hear the trains in neighboring basements. The London Underground report concluded that in-property noise from trains had been reduced from 48 Db(A) to 32 Db(A).