Products that solve your problems

Fastclip FE System

The Pandrol Fastclip system is a resilient, threadless rail fastening system with the unique Pandrol switch on-switch off system that enables fast and efficient track installation resulting in time and cost savings. For ballasted LRT/Metro the Fastclip FE assembly is designed typically for European category B tracks which is catagorised as suitable for axle loads of up to 18 Tonnes and curves down to 80 m radius. As a threadless system Fastclip is ideally suited to an environment where time for maintenance is limited and where the integrity of the fastening system is crucial for safety. The unique shape of the Fastclip installed perpendicular to the rail provides the opportunity for high speed remote track inspection, and the threadless design of the fastening, minimises the requirements for maintenance.

Head wash repair

The natural processes of wear and surface deterioration of rail steel can proceed at a rapid pace that results in a reduced service life. Rail corrugations initiate from: rail head de-carbonization (on new steel) and irregularities such as; rolling defects from the steel making process, contact fatigue defects, rail welds, rail joints, etc. The Head-Wash Repair Weld is a weld process designed to efficiently remove defects from the ball of the rail with minimal disturbance to the track. A familiar mold design allows a welding crew to undertake the Head-Wash Repair Weld quickly and easily when a standard 1” weld is unnecessary.

Multi Purpose Grinder

Grinding of rails has evolved as a maintenance technique to insert controlled artificial wear and manage wheel / rail contact stress. This maintenance strategy reduces rail wear, controls rail surface and sub-surface fatigue, controls rail surface plastic deformation, improves truck steering, improves the dynamic stability of rolling stock and improves rolling stock wheel life. By grinding a corrugated rail surface the wheel/rail dynamic loads are significantly reduced and the track structure (fastenings, sleepers and ballast) will last longer. The Pandrol Multi Purpose Grinder controls corrugations through preventative grinding.

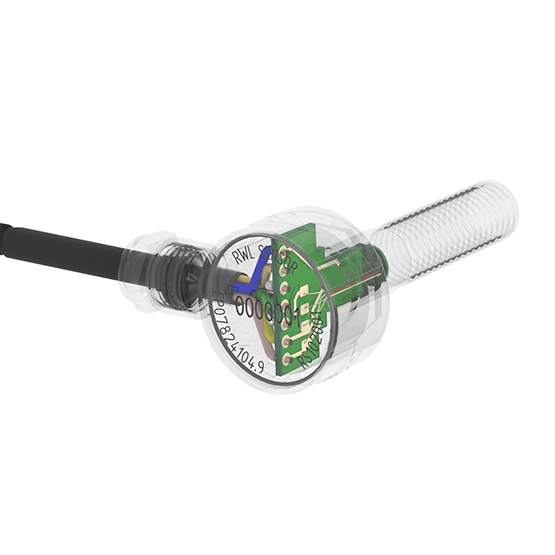

Pandrol Automatic Inspection System (AIS) WheelChex®

The Pandrol AIS uses a series of Pandrol MultiSensors™ to monitor force on the rail. Unlike traditional AIS that use bonded strain gauges, which are difficult to install and require high maintenance, these sensors are embedded in the rails and form an array which measures the force profile of each wheel as it passes over the system. This force profile is used to determine the roundness and smoothness of each wheel by monitoring the mean weight and peak force (from impacts) of the wheels.

A world of knowledge

Metro North, New York

MNR and LIR chose the Pandrol Automatic Inspection System (AIS) WheelChex®, which consists of 32 Pandrol MultiSensors™ in each of four tracks in the Park Avenue Tunnel under Manhattan; a total of 128 sensors per installation. The WheelChex® system, powered by Pandrol sensors, has been so reliable that Metro-North has selected Pandrol to deliver three ‘Train Fault Detector’ (TFD) houses, adding hot wheel and bearing detection, along with enhanced data analysis. This was a ‘first’ in the US rail transit industry in combining these measurements into one location.

Pandrol’s innovative TFD system provides a comprehensive overview of wheel and axle condition and will allow the railroads to benefit from operational information in the form of messages and alerts to tell them if a particular vehicle is presenting a risk to the infrastructure. With new trending algorithms, this makes it possible to plan ahead and avoid some of the panic that happens when leaves fall on the line in autumn, when most wheel damage occurs.